simplicity through modern technologies

fitting: contact-free and relaxed

The helmet fitting is stress-free for parents and children: the child’s head is measured by orthopaedic technicians in just a few seconds by means of a 3D scan that requires no direct physical contact. This harmless process uses structured light and involves no exposure to radiation. All of the data to manufacture a custom-fit helmet are collated in just a short time.

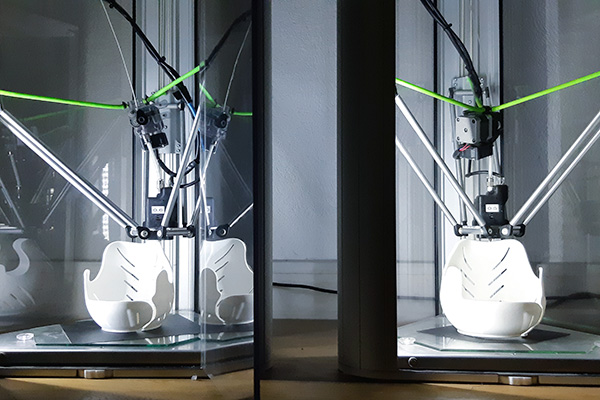

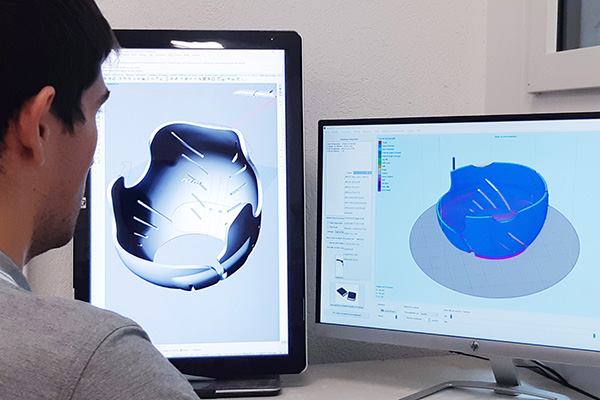

helmets: high-precision production through 3d printing

The orthopaedic technicians at orthethic produce the helmet individually for each baby according to exact measurements. The asymmetry is defined according to international standards; the head is then modelled virtually using cutting-edge CAD/CAM technology. The specialists then produce the helmet in the Geneva workshop using 3D printing.

«all in white?» – not necessarily!

Of course, a helmet can be a little disturbing at first sight, but this is less the case when it is colourful or decorated with cheerful motifs designed to appeal to children. Orthethic has developed a proven water transfer printing process for the helmets and offers custom finishing on request.

comfortable to wear and easy to clean

3D printing enables us to make a helmet from especially thin, lightweight material that is still durable. The hypoallergenic 3D padding inside can be easily removed and washed – which is a big advantage for parents. The special surface of the material also ensures air is able to circulate to the baby’s skin constantly and moisture is removed, preventing skin irritation.